Engine Room Ventilation System

We are supplying of “ITALY Make” Engine room ventilation equipment for vessels of all sizes and operating conditions. Ensuring your engine room equipment is free from salt mist and spray is just the starting point of a better engine room ventilation solution for vessels. Having the correct ventilation setup will ensure more affordable operating costs, better conditions, and an extended lifespan of your equipment.

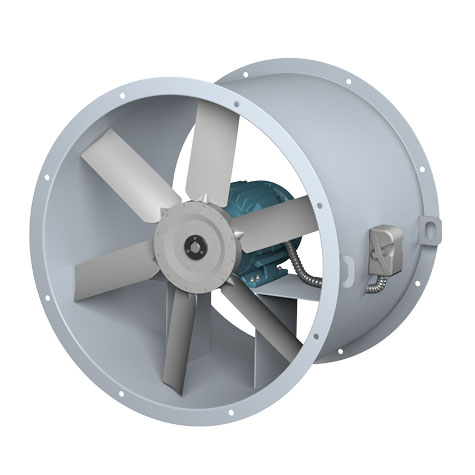

Ventilation Fan

The axial fans series use high efficiency aerofoil profile impellers. They are suitable for compartments ventilation where is required large capacities at pressure relatively low, like yachts and mega-yachts engine rooms. This series, differently from normal axial fans, presents higher performances. These blowers can work with the axis vertical or horizontal oriented that allows to attach the blower to ceiling or wall. All blower are reversible type, but obviously they have a preferential flow direction. Suitable for clean air or slightly dusty conveying with temperature from -20 °C to +80°C in continuous service. The motors are suitable for inverter command at variable rpm.

Fire Damper

Multi-wings fire damper with automatic control mode, certified for inclusion in ventilation system in steel, aluminium or fiberglass deck and bulkhead class A0/A15/A30/A60. Completely made in stainless steel grade AISI 304 or AISI 316. Electrical, pneumatic and explosion proof actuators are available (ATEX rated) To ease installation GMFD dampers are designed to be suitable for mounting in any attitude with the airflow in either direction. The special wings design at variable pitch maximises the free cross section area, ensuring an easy air flow. The blade aerodynamic profile allows the air flow into the duct without any significant noise or pressure drop.

Certification

- RINA Approval to IMO Fire Test Procedures Code, Annex 1

- Marine equipment directive 96/98/EC

- US Coast Guard (Product category 164.139)

Mist Eliminators

EMS 3500 Air Intake Mist Eliminator

EMS 3500 is a ready-to-install droplet separator for use as air intakes in marine and offshore applications. It is available in various material combinations and configurations to fit a wide range of operating conditions. EMS 3500 droplet separator provides high efficiency droplet separation and low pressure drop even at high face velocity. The droplet separator can be configured to most individual performance and installation situations, providing a cost-effective solution. Alternative material choices and drainage systems, as well as add-on features, like flanges and protection mesh, are just some of the configuration options.

EMS 3500 droplet separator is an excellent choice for air intakes in marine and offshore applications. It is best suited for keeping splash water, sea spray, mist and larger fog water droplets out of a ventilation system. Whenever the natural operating conditions are very harsh, the EMS 3500 provides excellent protection from water. This helps to reduce corrosion, to increase filter lifetime and to reduce moisture throughout the system. The unit is suitable for use at face velocities up to 7 m/s. Material certificates can be delivered for most materials upon request. Fractional efficiency curves for given face velocities are delivered on special request.

EMS 2800 Air Exhaust Mist Eliminator

EMS 2800 is a ready-to-install droplet separator for use in many application areas. It is available fit a wide range of operating conditions. EMS 2800 droplet separator provides high efficiency droplet separation and extreme low pressure drop even at medium face velocities giving energy saving operation. The droplet separator can be configured to most individual performance and installation situations, providing a cost-effective solution.

EMS 2800 droplet separator is an excellent choice for keeping rain, mist and larger fog water droplets out of building or marine ventilation systems. This helps to reduce corrosion, to increase filter lifetime and to reduce moisture throughout the system. EMS 2800 droplet separator is designed for use in many applications and for an easy integration into the structure. The unit is suitable for use at face velocities between 1 and 5m/s.